- Introduce

- Use formula

- Specification

- Advantages

- PDF Download

PDF

PDF

Plummer block units are available in various types and series. Therefore, to select the bearing unit optimal for machinery design, multiple factors, including the structure of machinery, operating conditions, performance required for Plummer block unit, specifications relative to the unit, marketability, and economic efficiency, must be comprehensively taken into consideration. The service life of the bearing greatly depends on the quality of selection.

If a bearing is used for a dolly under the following conditions, select the pillow type unit (UCP) with 10,000 hours rating life: radial load Fr is 12 kN (Fr = 12 kN), and rotating speed is 8 min−1.

(1) Find the required dynamic radial load rating Cr with using Formulas (4.4) and (4.5).

Speed factor

Life factor

Dynamic radial load rating Cr = Pr ·= 12 × fh fn

2.71 1.61

L10h 500

10,000 500 fh = 1/p =1/3 ≈ 2.71

fn = (0.03n)−1/p = (0.03 × 8)−1/3 ≈ 1.61

≈ 20.2 (kN)

(2) From Table 5.6, define safe factor fs as 2 ( fs = 2), and find the static radial load rating of bearing required C0r.

C0r = fs · Pr = 2 × 12 = 24 (kN)

(3) The unit is used for a dolly, and vibration or impact may occur. Thus, select UCP308J (Cr = 40.7 kN, C0r = 24.0 kN).

Procedures of the selection of standard Plummer block units

Procedures of the selection of standard Plummer block units

| Procedures of selection | Items to be examined | Operating conditions to be considered |

Reference |

| 1 Selection of type | · Pillow block type

· Flange type · Take-up type · Cartridge type · Hanger type |

Structure of machinery, mounting space, mounting dimensions | 3 Types (P.12) |

| 2 Selection of shaft dia. and dia. series |

· Bearing bore dia. : From 10 to 140 mm · Dia. series : 0, 2, X, 3 |

Rating life of bearings required, the load applied to bearings, rotational speed | 5 Life of bearing (P.30)

6 Bearing load (P.35) 7 Allowable rotational speed (P.42) |

| 3 Selection against atmosphere |

· L3 type

· Cover type · Stainless steel series · For high-speed use · For blower |

Environment (dust, mud water, high humidity, chemicals), rotational speed | 3 Types (P.12) (P.25)

7 Allowable rotational speed (P.42) |

| 4 Selection against temperature |

· Heat resistant type

· Cold-resistant type · Measures against the expansion · Grease supply |

· Grease supply | 3 Types (P.12) (P.25)

8 Operating temperature and bearing 10 Design of shaft and base (P.49) 14 Handling (P.63) |

| 5 Selection of installing to shaft |

· Set screw

· Adapter · Eccentric locking collar |

Rotational speed, load conditions, handling | 3 Types (P.12)

14 Handling (P.63) |

| 6 Selection of shafts | · Dimensional tolerance

· Adoption of shouldered shaft · Provision of set screw for shaft · Measures against the expansion |

Rotational speed, load conditions, bearing temperature | 3 Types (P.12) (P.25)

7 Allowable rotational speed (P.42) 10 Design of shaft and base (P.49) 14 Handling (P.63) |

| 7 Selection of strength of housings |

· Cast iron

· Cast steel · Pressed steel |

Load conditions, load directions, presence of impact | 9 Strength of housing (P.44) |

| 8 Selection of lubrication |

· Lubricating type

· Non-lubricating type · Centralized lubricating type · Greasing interval |

Environment, the importance of machine, bearing temperature, grease life | 14 Handling (P.63) |

| 9 Selection of maintenance and check | · Periodic inspection

· Grease supply |

Environment, the importance of machine, bearing temperature, grease life | 14 Handling (P.63) |

Plummer block Units need not be maintained or checked for standard purposes during operation.

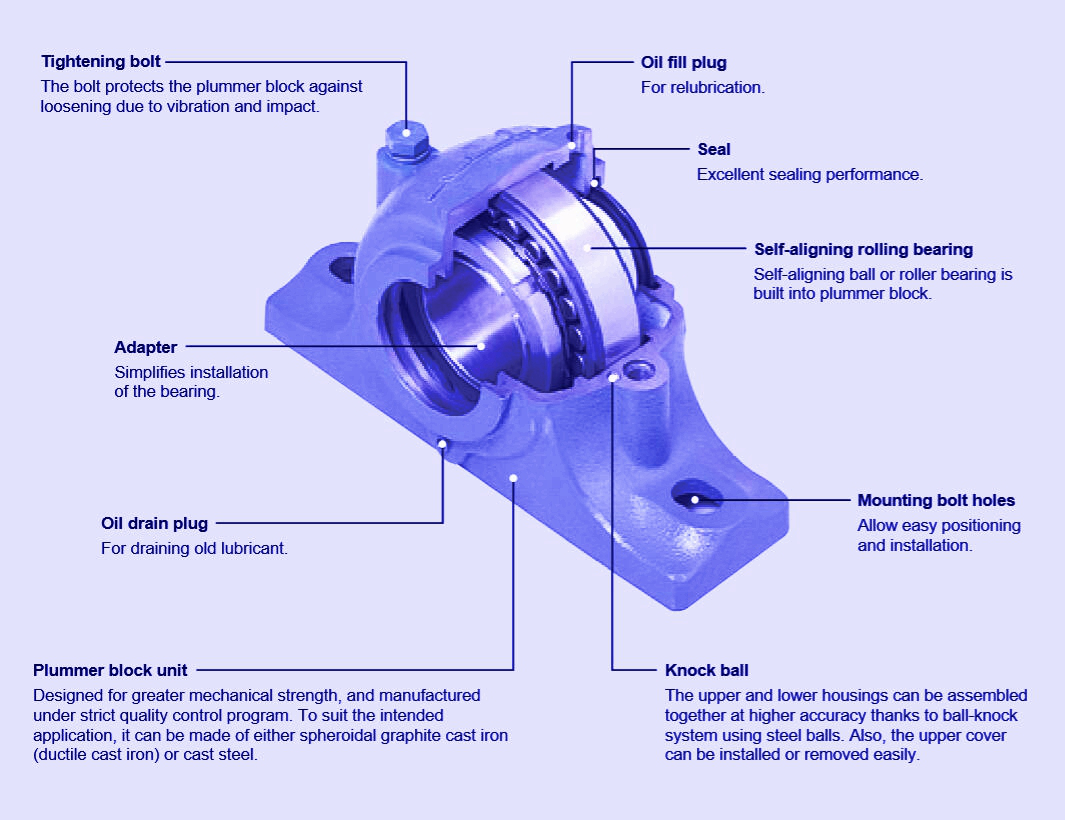

Plummer block Units Advantages

Plummer block Units Advantages

1. Simplified stockholding as a result of the modular concept. One housing size suitable for various shaft diameters.

2. High load-carrying capacity. • Depending on the operating conditions, double lip seals, labyrinth seals, felt seals, V-ring seals, or combined seals may be used. • Special seals are available by agreement.

3. Locating bearings centered using two locating rings of identical width.

4. Flat end faces on the housing base allow abutment against stops if high forces do not act on the locating face in a purely vertical direction.

5. Holes can be created at marked points on the housing for monitoring systems, fixing screws, parallel or tapered pins.

Universal paint coating for all outer surfaces of the housings not machined by chip-forming methods (color RAL 7031, bluish grey). The coating can be finished using all synthetic resin, polyurethane, acrylic, epoxy resin, chlorinated rubber, nitrocellulose, and acid-hardening hammer tone finishes.

Selection of Plummer block units PDF

Selection of Plummer block units PDF

Procedures of the selection of standard Plummer block units

Procedures of the selection of standard Plummer block units